The difference between adventure and adversity is attitude.― Janet Evanovich, Dangerous Minds

Ketchikan 8/7-8/18

I was looking for a quote about adversity but then did not really feel like they were what I was looking for and so I added adventure in my Google search and this popped up….

PERFECT!!! Will definitely remember, like a mantra

And so back to the tow…

As mentioned in the last blog, we were attempting to get into an anchorage safely but still needed a tow and ideally to Ketchikan, our ultimate destination and where we logistically could have a chance to fix our engine.

Since it was impossible to get into an anchorage safely, we stayed back in the Behm channel tacking back and forth waiting for Coast Guard. They did send a Rigid Inflatable AKA RIB our way. There were no private towing companies and as we discovered when our starter was acting up, TowBoatUS does not service AK.

I was extremely proud of all of us, Stephen, Karen, and myself, for how we handled our situation. Stephen was fantastic on the radio, his previous jobs do aid with his ability to communicate on the radio in an efficient and succinct manner. Karen remained very cool and allowed us just to do what we needed. She remained available for physical and emotional support if needed. As mentioned before, we were grateful to our friend, Matt Kalush, from Soldotna AK, who was able to incident command our situation a bit.

Coast Guard could hear us on VHF but we could not really hear them. Communication was broken and they sounded “in the weeds” as a common phrase used to describe poor audio feedback on the radio. Matt, who was familiar with Soulstice ( he and Amahra were crew on our 23-day passage from MX to HI) and us, was able to answer Coast Guard questions including what kind of folks are we and how capable is our boat. Additionally, there were NO OTHER BOATS of any shape or form in the canal to reach out to. Other larger vessels could tow us but none were even around. Our rescue was dependent on Coast Guard.

After we aborted now the 2nd anchorage, this time due to the wind dying to almost zero and then wind coming from the anchorage directly on our nose ( in the irons), we patiently waited in the Canal to see some lights reveal Coast Guard had arrived. They probably go 30 knots but reports were for a while that they had not even left Ketchikan. And yes, eventually, the lights were noted, red and blue, and I started to feel relief. I cannot say how Karen felt but Stephen reports he was more focused on setting a safe scene for them to pull up to Soulstice and arrange the tow. Also, I was very curious “how” to get towed.

We put all sails away and performed a hove-to, which basically arrests the boat in movement. It is even a storm tactic. We confirmed with CG when it was safe to approach Soulstice. They sized up our rig to make a determination of the best and safest way for a tow. It was decided that bow cleats would be used and their wide-diameter, multi-blade Dyneema line was used that allows for stretch for the tow. They arranged about 120ft of line to be paid out for our safe distance behind them. They suggested a watch during the tow to assure Soulstice would not stray too far starboard or port during the tow. Stephen locked off the helm to center and we created a 2-hour watch schedule with just him and I. We told Karen to try and get some rest.

It was a 7-hour tow at approximately 6 - 6.5 knots. Unfortunately, there were a few events during tow that caused concern. Coast Guards’ FLIR ( focused light infrared) was down and so they state their ability to see logs or other submerged objects was limited. During my watch, which was first, there was a LOUD BANG and THUMP on our hull!!! Stephen immediately got up out of bed, and I expected nothing less, as the noise was alarming.

Coast Guard recognized they went over this huge tree and also realized it could have harmed our hull. We could only do a superficial inspection above water and bilge checks but it was all good. We knew that an underwater inspection would be necessary once in port. And, again TWO other times they hit large logs that Soulstice also went head-on with. This is why we avoided nighttime transit in AK and BC ourselves but this was a RESCUE and regardless, we were at the mercy of these folks who came to save our bacon!!

The tow included hourly check-ins by the Coast Guard and eventually a sunrise arrival ( 0530am) to a loading dock. WE MADE IT!!! Soulstice was tied up safely, BUT What next????

Troubleshoot the cause of the problem, which we were expecting to be the heat exchanger after further discussion.

Stephen and I felt harried after the all-nighter but still too restless to go to sleep. We made a few phone calls once in port, basically, a round of calls to some of our mechanical friends who know boats to chime in on our predicament. Most agreed with us it was probably our heat exchanger. This is where raw water and coolant meet and then go through the engine to keep her cool. A head gasket was mentioned but we felt our symptomology was not consistent with this as the issue. The main thing we witnessed was the engine overheating and seeing a lot of coolant expelled from the wet exhaust.

The day was short due to our fatigue and that punchy feeling you get when overtired and overemotional. I felt like we were all very calm but the inside turmoil of feelings got to us all. And the weather went to crap as predicted and heavy wind and rain followed shortly thereafter.

Stephen, the day after the tow, he did dive down to evaluate our hall for any damage to the fiberglass. Luckily, he did not see any significant damage. We do have some slime on the hull and some growth, but this afforded him the ability to see where the logs made contact with the fiberglass, and there was only scuff marks. He used a bright dive light and scrub brush, in addition to tapping the hull out for any evidence of intrusion and nothing was noted. The shaft, prop, skeg and rudder were all without injury! This was a huge relief as a haul out would be a major project with fiberglass work. As I was on deck being a look out for him with other vessel traffic, a HUGE sea lion was in the harbor only 50 ft away but luckily Stephen had just finished his inspection and was able to get out of the water quickly😳🤓 He reports they had a moment of eye contact…

The next few days were solemn but progress was made each day to rectify our engine issue. We were able to get a part delivered from Georgia to Seattle ( Hatton Marine - our dealer) and then overnighted via GoldStreak from Alaska Airlines.

No diesel mechanics were available in Ketchikan to help us. There are 4 and they are all too busy with larger commercial operations. We were able to get phone help from one gentleman, Jerry, and then we solicited guidance from another mechanic, Jamie, who is with Southeast Diesel and Electric. We walked into his shop and he very kindly walked us through our installation to include some tips about evaluating if water did get into our engine. This included manually using the flywheel on the crankshaft and if turns were successful then it was felt there was no water in the cylinders. He also recommended draining the coolant that was in the current exchanger.

He could not help us in person but his time and attention were so appreciated. Stephen had been intensely studying his Yanmar service manual and I too evaluated these pages that gave specific diagrams of our engine but also troubleshooting guidance. Karen had already left at this point in time, having her send-off 2 days after our arrival. We were sad to see her go but also knew the cabin/salon would be torn up and her departure was helpful as space becomes at a premium when doing boat projects.

After ordering our part, it took only 2 days to arrive as we had it overnighted from Georgia to Seattle. Installation took place on Friday, exactly 5 days after our tow arrival ( Monday 8/7). There was a bit of hesitation on the front end of ordering because we were trying to decide if we needed just the tube bundle, which is just one part of this heat exchanger or if the manifold was damaged, the entire thing. Our pressure test failed, meaning when we pressure tested our heat exchanger it lost pressure ( 21 psi down to 15 in 3 minutes) and we decided to get the entire element because “what if” there was a crack or a leak somewhere else in the manifold we could not visually see or inspect and then we are back to square one. It was not cheap but would give us peace of mind as after this we would be heading into Canada and now you would be importing parts.

It is imperative we start to move farther south before the weather starts to become too challenging to move the boat and the weather windows are short. This was already happening with low after low forecasted during our weeks in Ketchikan. That also made us anxious but you can only do what you can do. We ran into Miss Treva, John, and Chase, incidentally again in Ketchikan. They got their aquamarine drive installed and just arrived at Ketchikan. Due to the weather pattern, they were planning to leave ASAP and encouraged us to do so as well.

The installation went super smooth UNTIL… Stephen had a stud fracture flush after torquing it. This was Friday evening and we went to bed with a terrible feeling as we were not sure what to do… Did we damage the engine block in which the stud threaded into? We did not get additional hardware, but we did order additional gaskets and O rings but no extra bolts, studs, or nuts. Most people do not as hardware failure is rare per Hatton Marine but that was one thing that Jamie the mechanic mentioned. Well, now we needed several phone a friends…

The next morning, Stephen and I woke up discussing again the entire situation. During this time a light bulb went off that Stephen over-torqued the bolts. He realized this after reviewing a Yammer parts manual that showed our bolts are M8 but he torqued to M12 specs. He did this because the bolt head fit a 12 mm wrench and he went with those specs. He was devastated by his mistake and said it was a “rookie” move. There was NO instruction manual with the element nor a label on the parts. Yanmar changes their parts # every 6 months so he has never kept a parts manual around due to this but our buddy Matt found one online and after reviewing which kind of stud and bolts that are used for this installation, it revealed the M8 size.

Unfortunately, I did not know any better myself to double-check him but you can bet I learned a lot during this installation and that will forever stay in my brain. Our heat exchanger is installed by sliding the new element over 2 studs that are threaded into the engine block, but there are 6 other bolts that go in as well. Had the stud not fractured, we may have thought everything was fine and then possibly had a problem down the road and not EVEN realized the grave error.

After talking to several folks we decided to search for grade 8 M8 size bolts in town as replacements. Our biggest hurdle was to remove all the bolts and hope no other ones would fracture either and that we could get the stud out without damaging the engine block. A big request to the Powers that be… And drum roll…. We were able to remove all the bolts and the stud without any damage !!!!! PHEEWWW! Such a feeling of relief!! But now what? After lots of conversation and the inability to find Grade 8 M8 sized bolts but we did find M8 size Grade 5 that we decided to reinstall the old bolts except for the stud. Prior to making that decision we visually inspected the old bolts for necking, thread-rounding or any other potential defect from the inadvertent over torque. Mark Welch, our metals expert, marine architect and good buddy helped tremendously in addition to Larry Schmidt and Matt Kalush! We appreciated everyone’s input and time given to aid with our decision making. We replaced the fractured stud with a new bolt and because the torque specs were much lower we felt good about the exchange, the specs were well within range of the grade 5 M8 bolt. Once in Blaine, WA where we have more resources, we will replace that bolt.

We waited until the next morning to fire her up. We just wanted to revel in our success and luck for a good night’s sleep. That way if she did not start up or overheat the next day or whatever, it was with a good night’s sleep under our belt to deal with the situation. Luckily for us, she started up with no problem and no OVERHEATING! YEEAAHHH/ YIPPEEE!! Another success!! We got busy after that to do several coolant flushes, put in our new coolant, and do an oil change and fuel filter changes, which were due as well. We did send an oil sample a few days back to an outside lab but our oil looked good. Not milky as if water had contaminated our fuel source.

Stephen was on Cloud 9 after all these projects and I was elated myself. We were no longer disabled. The next hurdle was WEATHER. When could we move south? We hurried up to get provisioning done, fuel filled and evaluate the weather. Well…. It was no GO! Too many lows with high winds coming from the South ( not good as that is the direction we want to go) and the realization was we had to wait for a better weather window.

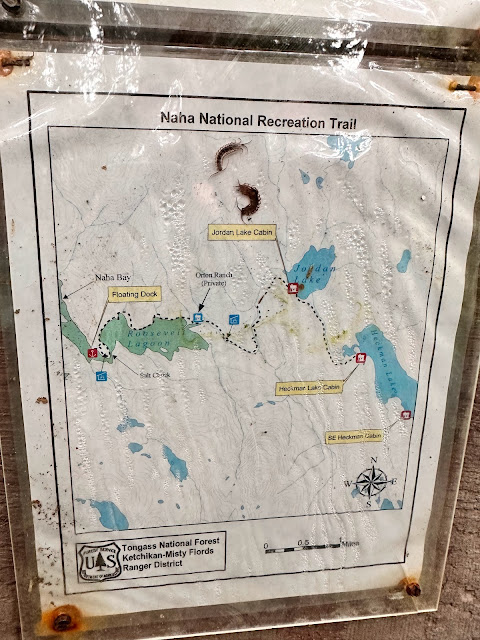

We were bummed but realized we could enjoy Ketchikan a bit now that our days were not filled with just fixing Soulstice. There were some hikes I wanted to do and so we made plans to hike Deer Mtn the next day. It is a 2800ft climb and 6.7 miles out and back. The TH was accessible by walking as well. Carlanna Hike, 2224ft climb and 5.4 out and back was also within walking distance to get to the TH. Other activities were some frequent visits to the Asylum Bar which has $3.50 drafts to include a 9% IPA called Asylum we found quite tasty and Monday nights there offers FREE FOOD!! Yep! Who does free food anymore??? We enjoyed a delicious smoked salmon chowder with leeks, potatoes, and carrots with bread and salad.

Now we were starting to feel like locals a bit. We had already several bus rides under our belt including several visits to the recreation center which is like a YMCA of sorts. Ketchikan is a cool area and has a lot to offer. When the weather is nice it is even better - ha!

Our next weather window is Friday, which is almost 2 weeks from when we arrived. The winds will be NW so blowing up our skirt which we prefer but still good wind. We will sail most likely as long as the opposing waves with current do not hinder our progress. The next stop is Prince Rupert and check back into Canadian Customs.

Sailing has lots of up and downs, with highs high and lows low. I still struggle with the loss of control I feel at times when dealing with mechanical issues with the boat, unsuitable weather conditions, etc... Manage your expectations! ( thanks Kalush's) still is a great mantra as well. This type of travel requires patience, tolerance, and careful execution and I am grateful that my best friend, Stephen, has these skills to help keep me on course when I let my guard down at times and start to get frustrated. I try to do the same for him. We are a good team!

Starboard stern pic

Loading dock - our home for a week

Rainbird Trail

Did a hike on karen's last full day to break up the stress and get outside

Ketchikan's local activities

After Karen left ( pescatarian) we decided to feast on some meat! and an amazing crab dip!!

M8 and M12 are very different in torque specs. Also not to mention these bolts have a size 7 on them and it recommends only 60% of the torque spec ( which we did but initially for the M12 so 53 lbs/ft vs the 18 lbs/ft recommended - YIKES

Bus riding in Ketchikan- only 2 bucks each way but bought a discounted 25 pass ticket

Luckily the loading dock is very close to Safeway fuel:)

Walked 1 mile to ferry dock, ferry across the channel to the airport and ferry back. Ferry ride 15 mintues. Took no more than an hour to include a walk back to Soulstice - grateful for the location's conveniences!

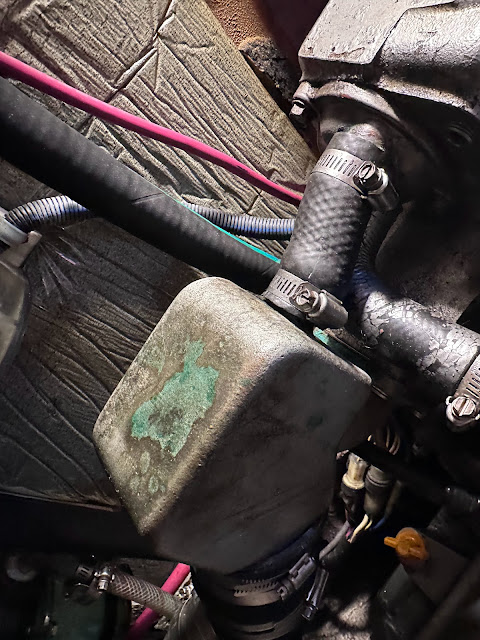

Old heat exchanger on the right ( has blue temp cap on it) Coolant reserve in a plastic white container on higher right side)

Mixing elbow and hoses. This sits behind the heat exchanger and is the interface between the coolant and freshwater system and the raw water and salt water system.

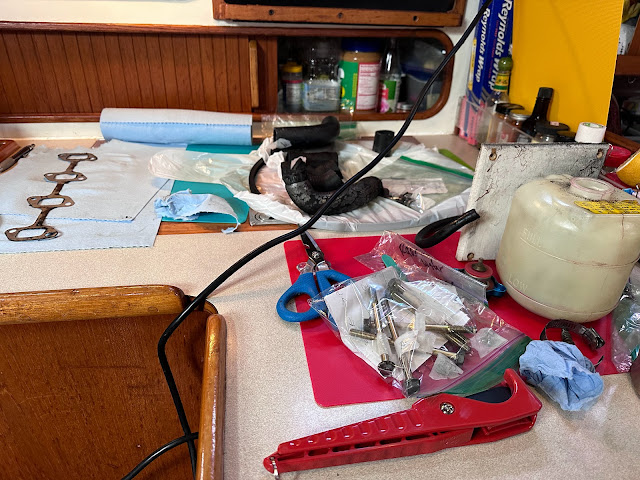

Project mode on Soulstice- galley countertop unusable for food prep

Yanmar service manual - torque specs on here

New heat exchanger

Old heat exchanger removed

space to access the engine under our companionway steps - tricky exiting the boat once these are removed, thank goodness for a hand rail above this area

If you look closely you see 2 studs sticking out from engine block- this is what heat exchange slides onto and then an additional 6 bolts are placed for securing in heat exchanger to engine block. This does not include 4 hoses that had to be removed and replaced.

The SNAP was deafening and immediately our hearts sunk

Needed a beer that night...

Finally, some nice weather moving in - this was after a week of torrential rain and wind

Celebration evening at the Asylum Bar - Smoked salmon chowder and yummy local IPA

Oh and notice Stephen's cute haircut!

Summit full of an incredible cloud view - HA

Window view on way down could see - on way up this was socked in

compass reading from the summit